Top 10 Tips For Devil666 Indonesian Online Gambling Platforms On Licensing And Regulation Understanding the Devil666 Slot Indonesian regulations and licensing is crucial when evaluating the online gambling platforms. This will enable you to have a safe and secure gambling experience. Below are the top 10 recommendations for Oxplay Indonesian bettin

Good Advice To Picking Windows Microsoft Office Professional Download Sites

What To Look For When Buying Windows 10/11 Home/Pro/Pro/Pro And Pro Products? Knowing the type of Windows 10/11 Pro or Windows Home product license key you're purchasing is vital. Different types of licenses have different rules, limitations and fees. These are the top 10 tips for understanding and selecting the right license:1. What is the differe

Recommended Reasons On Deciding On ASIAN2BET SLOT Sites

Top 10 Tips For ASIAN2BET Indonesian Online Gambling Platforms In Regards To Security To protect your personal and financial data and ensure a safe gambling experience online in Indonesia, you need to ensure that the platforms are safe. Here are the top 10 tips for evaluating and ensuring the safety of ASIAN2BET Indonesian online betting platforms:

Top Facts For Selecting TAJIR4D Websites

The 10 Best Tips For Paying Options On TAJIR4D Indonesian Online Betting Platforms When evaluating TAJIR4D Indonesian online betting platforms Payment options are a critical factor. Payment options' accessibility, convenience, and security can have a significant impact on the experience you have when betting. Here are the top 10 tips regarding eval

Great Advice To Selecting Rajatogel Sites

Top 10 Tips For Regulation And Licensing Of 7rajatogel Indonesian Betting Platforms When looking at betting sites online in Indonesia knowing the regulations and licensing environment is vital to ensure a safe and legal experience. These are the top 10 tips regarding licensing and regulation for 7rajatogel Indonesian betting sites:1. Verify Local L

Edward Furlong Then & Now!

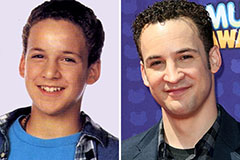

Edward Furlong Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Marla Sokoloff Then & Now!

Marla Sokoloff Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now!